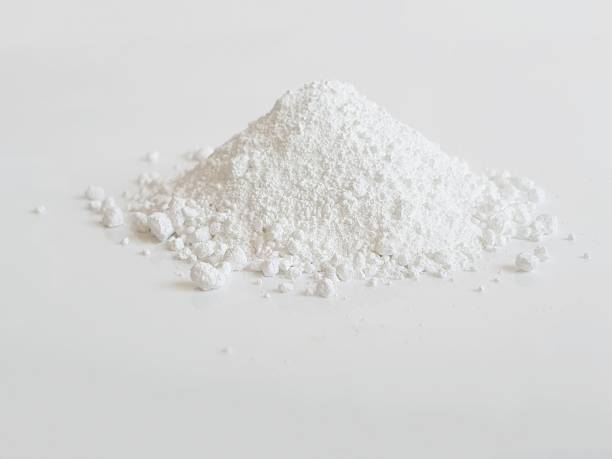

Understanding the Different Zinc Oxide Industrial Uses in Manufacturing Today

To a formulist, zinc oxide is something more than an essential, singularly useful chemical compound. Ever since Burch’s (1942) investigation of zinc oxide, a wide variety of industries have adopted this new material engineered for stability, non-toxicity, catalytic activity, among other properties. Here are five major zinc oxide industrial uses in manufacturing.

- Rubber Industry

Zinc oxide is one of the essential additives in rubber manufacture, and used as an active agent during vulcanization. Therefore the addition of such compounds enhances the strength, durability, and elasticity of rubber.

It also increases the heat resistance of rubber, which makes the material suitable for tires, footwear and industrial rubber goods. This incorporates the use of the compound in the curing process of rubber where the rubber comes out bearing the desired properties.

- Paints and Coatings

Zinc oxide is a popular ingredient in paints and coatings due to its excellent UV protection and anti-corrosive properties. It is commonly used in outdoor paints and coatings to protect surfaces from the damaging effects of UV radiation and moisture. Its antimicrobial properties also help in preventing the growth of bacteria and fungi, making it a key component in high-performance paints for both industrial and residential use.

- Cosmetics and Sunscreens

Zinc oxide is a common ingredient in cosmetics, particularly in sunscreens and lotions. Its ability to block UV rays makes it highly effective in protecting the skin from sun damage. Zinc oxide works by reflecting UV radiation away from the skin, preventing sunburns and other skin-related issues. It is often preferred over chemical sunscreen agents due to its non-toxic and gentle nature, making it suitable for sensitive skin.

- Electronics and Electrical Components

One of the important zinc oxide industrial uses is in the electronics industry, particularly in the production of semiconductors and electrical components. It is used as an insulating material and in varistors to protect electrical circuits from voltage spikes. Zinc oxide’s ability to regulate electrical current and prevent overheating makes it essential in the manufacture of resistors, capacitors, and other electrical components.

- Ceramics and Glass Manufacturing

In the ceramics and glass industries, zinc oxide is used as a fluxing agent. It helps lower the melting point of glass, facilitating its easier shaping and molding. Zinc oxide is also used in the production of certain ceramic glazes, enhancing their durability and color. Its high thermal stability makes it an ideal material for use in high-temperature applications within these industries.

The versatility of zinc oxide makes it a crucial component in modern manufacturing, with its diverse industrial uses playing a key role in the production of various products that improve our daily lives. Its zinc oxide industrial uses span multiple sectors, making it an essential material in numerous industries.